1.2 Expansion Joint Production - Step-by-Step Guide

Hand built products take over where stock production stops. These designs are engineered specifically to the application, so each is more dependable and long lasting. Molded expansion joints are limited in size, shape, materials and function to repeat applications where demand justifies the cost of molds. Industrial needs are seldom so cut and dried as the parameters of the application usually determines size, shape, and material preference. More often than not, the engineer’s only option is to customize. And that’s where Mercer Rubber excels.

We build expansion joints, duct connectors, and hoses in a broad range of shapes, sizes and configurations. Custom units include rounds; squares; rectangles; concentric and eccentric reducers; 30°, 45° and 90° elbows; offset connectors and even tees. Flanges can be created to match any design configuration, and ends may also be slip-on and built-in threaded or welded nipples. At Mercer, size is not an obstacle. We can build piecesfrom 3/4" to 17" in diameter, and we can build then in virtually every type of reinforcement fabric and steam cured polymer or over Teflon™ liners.

Mercer’s engineering team is always on-site to lend their expertise at the design stage, and their guidance during production.

This brochure will demonstrate the dedication and the effort we put forth to create a single, customized product. Our customers appreciate that. We know you will too.

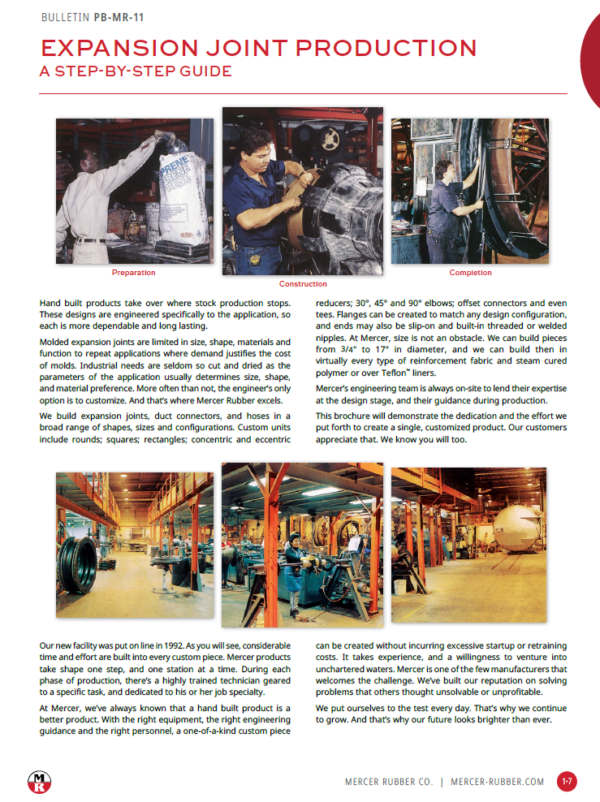

Our new facility was put on line in 1992. As you will see, considerable time and effort are built into every custom piece. Mercer products take shape one step, and one station at a time. During each phase of production, there’s a highly trained technician geared to a specific task, and dedicated to his or her job specialty.

At Mercer, we’ve always known that a hand built product is a better product. With the right equipment, the right engineering guidance and the right personnel, a one-of-a-kind custom piece can be created without incurring excessive startup or retraining costs. It takes experience, and a willingness to venture into unchartered waters. Mercer is one of the few manufacturers that welcomes the challenge. We’ve built our reputation on solving problems that others thought unsolvable or unprofitable.

We put ourselves to the test every day. That’s why we continue to grow. And that’s why our future looks brighter than ever.

Attached Files

| File | Action |

|---|---|

| 1.2 Expansion Joint Production - Step-by-Step Guide.pdf | Download |

- Version

- Download 330

- File Size 1.47 MB

- File Count 1

- Create Date February 15, 2024

- Last Updated February 15, 2024