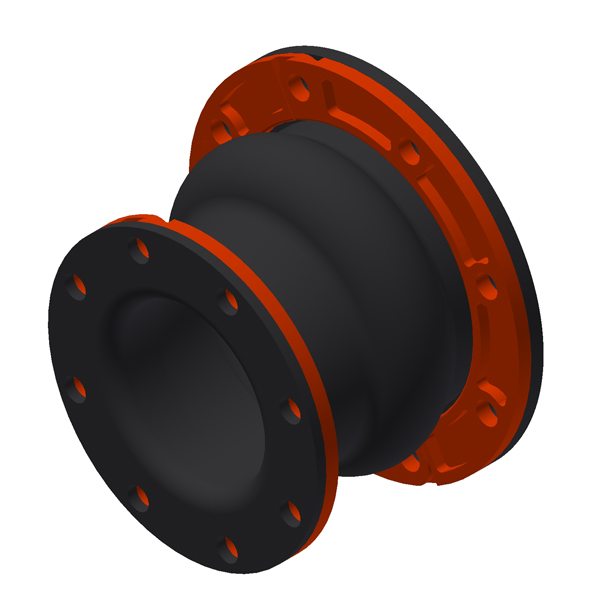

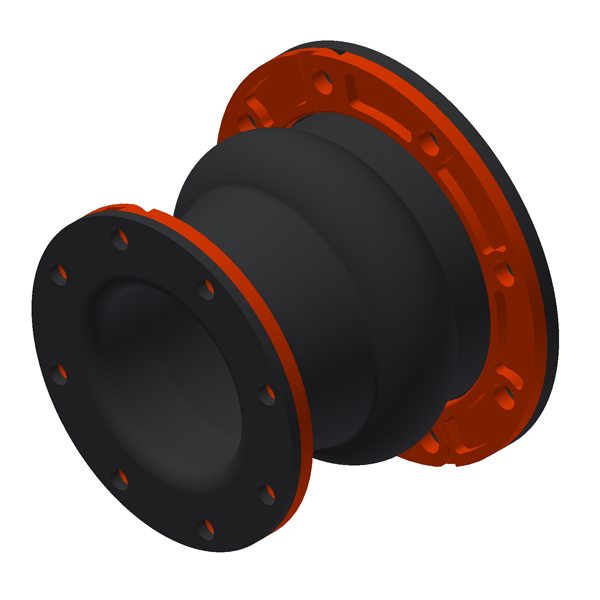

SFDCR

SFDCR SFDCR twin sphere reducers eliminate the need for cast iron or steel transition pieces usually found on both ends of pumping systems. Since steel reducers are eliminated,there are space, cost and labor savings. The SFDCR has a wide range of applications. Safeflex expansion joints are molded and vulcanized in hydraulic presses. This high pressure…